您现在的位置是:首页 > Application > Full size inspectionFull size inspection

Full size deviation detection service

![]() 2023-07-06 23:17:39Full size inspection0people have gathered to observe

2023-07-06 23:17:39Full size inspection0people have gathered to observe

IntroductionFull size deviation detection service is a service that detects and evaluates the size deviation of objects or products. Dimensional deviation refers to the dif

Full size deviation detection service is a service that detects and evaluates the size deviation of objects or products. Dimensional deviation refers to the difference between the actual measured value and the Design specification. By conducting full-scale deviation testing, it is possible to ensure that the dimensions of the product meet the expected requirements and promptly detect and correct any manufacturing deviations or defects.

Full size deviation detection services typically include the following steps:

Measurement and data collection: Use precision measurement equipment and tools to measure various dimensions of objects and collect corresponding data. This can involve the use of sensors, measuring instruments, optical equipment, or three-dimensional scanning technology.

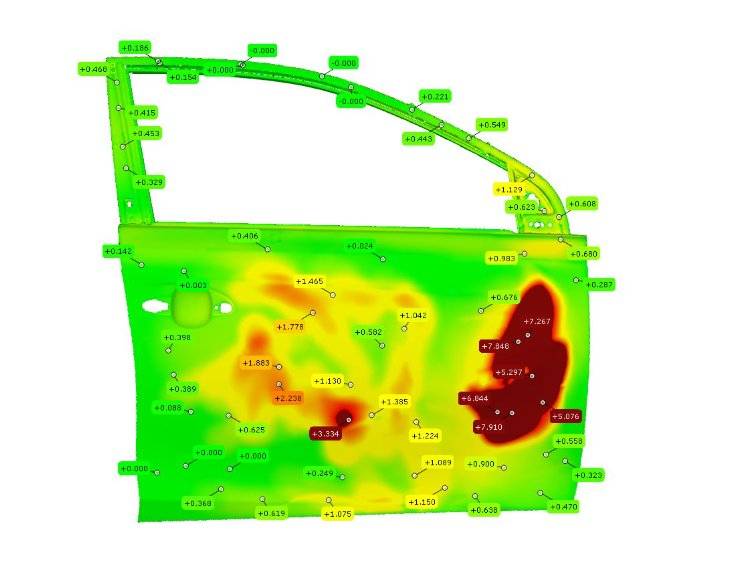

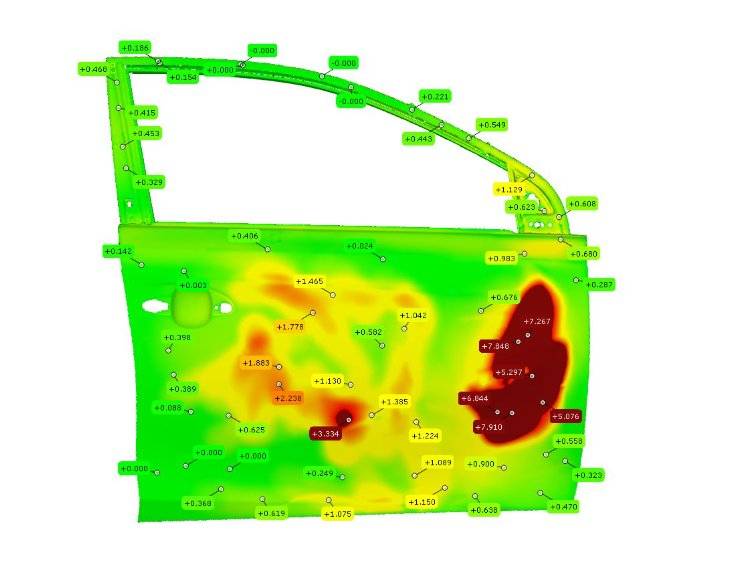

Data analysis and comparison: compare and analyze the actual measured data with the Design specification to determine the existence and extent of dimensional deviation. This can involve the use of statistical methods, image processing techniques, or geometric analysis software.

Deviation assessment and reporting: Based on comparison results and analysis data, evaluate the impact and severity of dimensional deviations. Generate detailed inspection reports, including numerical values of dimensional deviations, graphical representations, and related data analysis.

Deviation correction and improvement: Based on the testing results, take appropriate measures to correct dimensional deviations or improve the manufacturing process. This may involve adjusting production equipment, optimizing process flow, or adjusting product design.

Full size deviation detection services are usually provided by professional measurement and testing personnel with rich experience and professional knowledge, capable of accurately evaluating dimensional deviations and providing corresponding suggestions and solutions. These services can help customers improve product quality, reduce defect rates, and meet relevant standards and requirements.

Full size deviation detection services typically include the following steps:

Measurement and data collection: Use precision measurement equipment and tools to measure various dimensions of objects and collect corresponding data. This can involve the use of sensors, measuring instruments, optical equipment, or three-dimensional scanning technology.

Data analysis and comparison: compare and analyze the actual measured data with the Design specification to determine the existence and extent of dimensional deviation. This can involve the use of statistical methods, image processing techniques, or geometric analysis software.

Deviation assessment and reporting: Based on comparison results and analysis data, evaluate the impact and severity of dimensional deviations. Generate detailed inspection reports, including numerical values of dimensional deviations, graphical representations, and related data analysis.

Deviation correction and improvement: Based on the testing results, take appropriate measures to correct dimensional deviations or improve the manufacturing process. This may involve adjusting production equipment, optimizing process flow, or adjusting product design.

Full size deviation detection services are usually provided by professional measurement and testing personnel with rich experience and professional knowledge, capable of accurately evaluating dimensional deviations and providing corresponding suggestions and solutions. These services can help customers improve product quality, reduce defect rates, and meet relevant standards and requirements.

Tags: Full size deviation detection service

Great! ()

Previous article:Full size testing service for product sample verification

Next article:Full size inspection service

Related articles

- Full size testing service for product sample verification

- 3D scanning inspection service: exploring quality control innovation in the digital era

- Full size inspection service

- CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

- Full size deviation detection service

RandGraph+Text

CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

With the rapid development of technology and the continuous progress of manufacturing, the demand for high-precision and high-efficiency quality control in mode

3D scanning inspection service: exploring quality control innovation in the digital era

With the rapid development of digital technology and the continuous progress of manufacturing, quality control has become crucial in the modern industrial field

Full size inspection service

Full size inspection services are typically used to measure and verify the size and geometric shape of objects or products. This service can play an important r

Full size deviation detection service

Full size deviation detection service is a service that detects and evaluates the size deviation of objects or products. Dimensional deviation refers to the dif

| Notes and comments (There are comments) |

Click Ranking

Full size inspection service

Full size inspection service- Full size inspection service

- Full size deviation detection service

- Full size testing service for product sample verification

- CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

- 3D scanning inspection service: exploring quality control innovation in the digital era

TAGS

Guess you like it

- CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

- 3D scanning inspection service: exploring quality control innovation in the digital era

- Full size deviation detection service

- Full size testing service for product sample verification

- Full size inspection service